Do you feel that? That crisp breeze in the air that portends the end of summer and with it, the end of Sprudge’s Build-Outs of Coffee feature series. But don’t worry, we’ve still got some time left before fall is officially here. Still, what better place to celebrate that first autumn breeze than a city known for its gale forces? I’m of course talking about Chicago, Illinois, the Windy City, where Sputnik Coffee is keeping the city’s long coffee tradition alive with an all-new roasting facility and cafe space.

Nearly two years in the works, the 28,000-square-foot facility was scheduled for demolition before Sputnik took over. Now, the space will be divided amongst a roastery, a cafe, and a coffee-themed event venue. It’s still about a month and a half away from opening, so let’s check in on the progress of the expansive new space for Chicago’s Sputnik Coffee.

As told to Sprudge by Vova Kagan.

For those who aren’t familiar, will you tell us about your company?

Sputnik Coffee started six years ago with a crazy decision to buy an old US Roaster Corp 5 kilo on Craigslist. We put it into a friend’s basement in Logan Square. Our goal was to make craft coffee more accessible and affordable in Chicago.

Can you tell us a bit about the new space?

Two years ago now we found a 28,000-square-foot brick warehouse that was very close to being demolished by the city. It was way too big for what we needed but it was the only space we could find that would allow us to stay in our community.

We started the gut rehab a year and a half ago and even did our own roof to keep costs down.

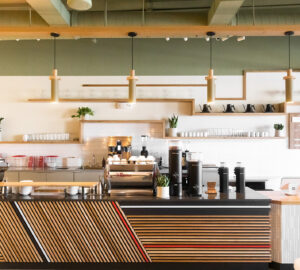

The new facility will allow us to buy coffee directly from the source and increase our overall capacity to meet demand. The coffee roasting side is about 15,000 square feet with a 2,000-square-foot cafe. We are putting in a huge glass wall that will allow cafe regulars to watch the roasting process.

The cafe will have a variety of seating options and will include a larger table for community gatherings.

The remaining 13,000 square feet will be turned into a coffee themed event venue called “The Roastery.” We can’t wait to caffeinate future weddings with shots of espresso!

What’s your approach to coffee?

We want to welcome more people to the craft coffee community by giving them an affordable coffee that’s a step up from what they are currently drinking. Customers often tell us that we were one of the first craft coffee bags they tried at the store given how affordable it was. After that they usually never look back.

Any machines, coffees, special equipment lined up?

A new 60kg IMF roaster plant from Italy that is a nice step up from our little red 15kg IMF.

We are setting up a restored vintage canning line that will allow us to package coffee in more sustainable vacuum sealed cans.

A four-group La Marzocco Linea S, two matching red Mazzer Robur S grinders, and a Mazzer Super Jolly will help us keep up on the cafe side. A TONE Touch 1 will keep the drip coffee flowing.

How is your project considering sustainability?

Firstly, we decided to rehab the warehouse instead of building a new building as the carbon footprint is half of building new. Materials were reused or repurposed wherever possible. For example, we carefully deconstructed the safe with three foot thick walls to save the brick. In total over 30 pallets of old Chicago brick will be reused in other projects around Chicago.

On the production side our goal was to increase production capacity while decreasing natural gas usage. IMF roaster technology, reuses hot air from roasting to clean the exhaust. This results in 50% less natural gas use than a similar 60kg roasting operation with a separate afterburner.

We believe that fully recyclable metal tins are the future of coffee packaging for both whole bean and ground coffee. Traditional coffee packaging, even with nitrogen, loses flavor quickly as it sits on the grocery store shelf and results in a lot of thrown out coffee. Vacuum packing removes all oxygen and is the best way to preserve the taste of craft coffee while expanding our reach to more consumers who may not own a grinder. As an added bonus customers can also come back to our shop to have their cans refilled!

We plan on having some bees on the roof and planting native prairie plants around the building.

The next phase of the project will be putting up solar panels to help offset our power requirements.

What’s your hopeful target opening date/month?

October 31, 2023

Are you working with craftspeople, architects, and/or creatives that you’d like to mention?

We’d like to thank all of our customers, everyone who has ever stopped by our shop or bought a bag of coffee. We would not be here today without each and every one of you.

Our project would not be where it is without the help of our general contractor Robert Meltzer and architects Agustin Gomez and Joanna Ruiz of Wallin Gomez Architects.

We’d like to give a special shout out to Paul of Walnut Spaceship who is helping us with the cafe design.

Our contractors have been working long hours to move our dream forward.

Sam and Fernando from Surface Plus Inc

Bob Fisher from Evanston Lumber

Jaime Alvarez from Alvarez Electric

Alex Soloview from DWV Plumbing

Robert Kamysz from Miron Heating & Cooling

Fidel Vega from DeVega Concrete

Gene Melnytschuk from Forbes Fire Protection

Macario and Cesar Nevarez from MN Construction

Alex Vajagic from MJ Iron

Thank you!

Photos by Greesha Kagan