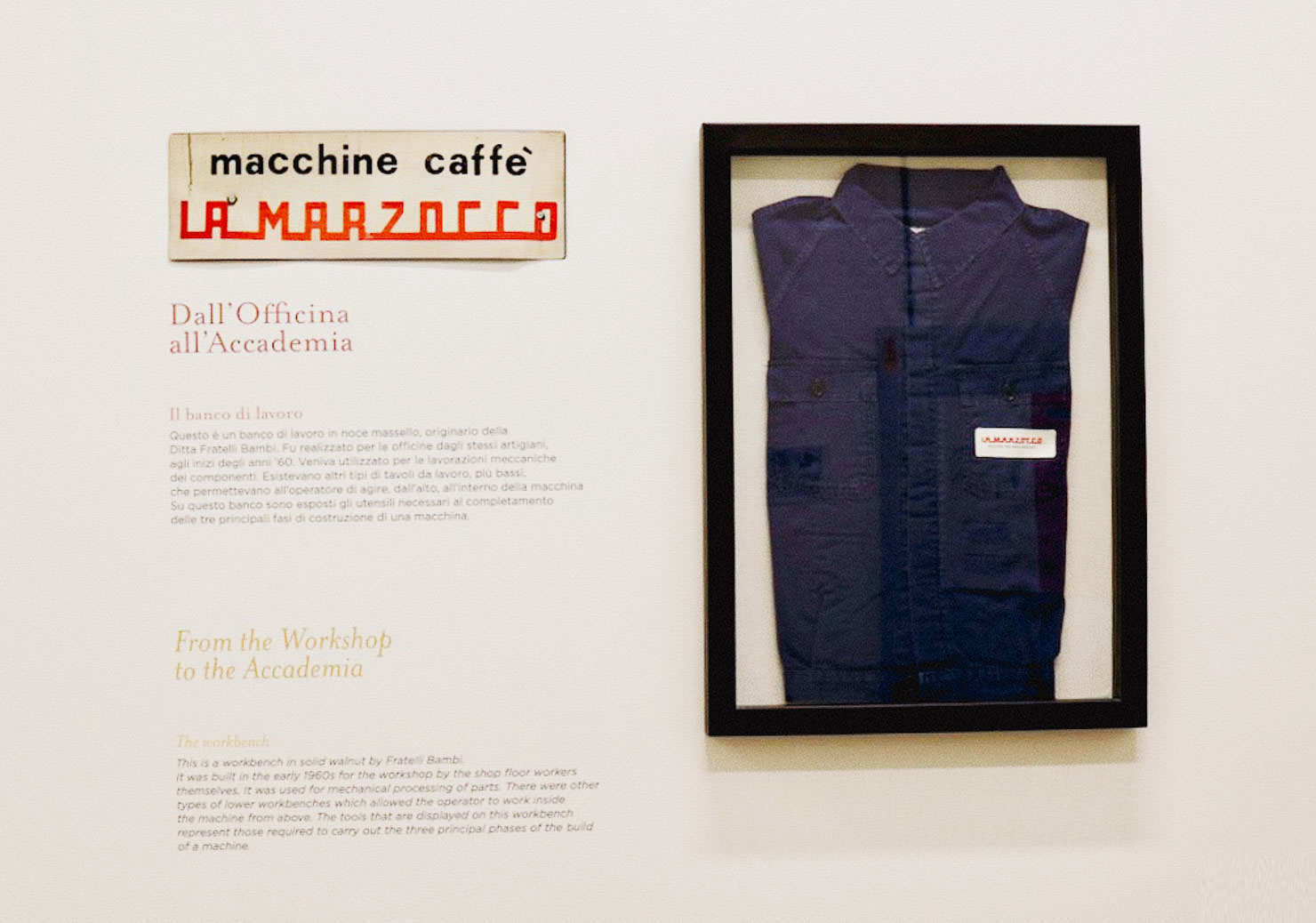

A few short weeks ago, we brought you a fresh round of reporting from inside Accademia Del Cafe Espresso, the global visitor’s center, interactive museum, education hub, and brand flagship of our partners, the noted Florentine espresso machine manufacturers La Marzocco. In this story, we took readers throughout the main floors to experience the coffee, cuisine, history, education, and interactive experience of Accademia.

But there is more to the story.

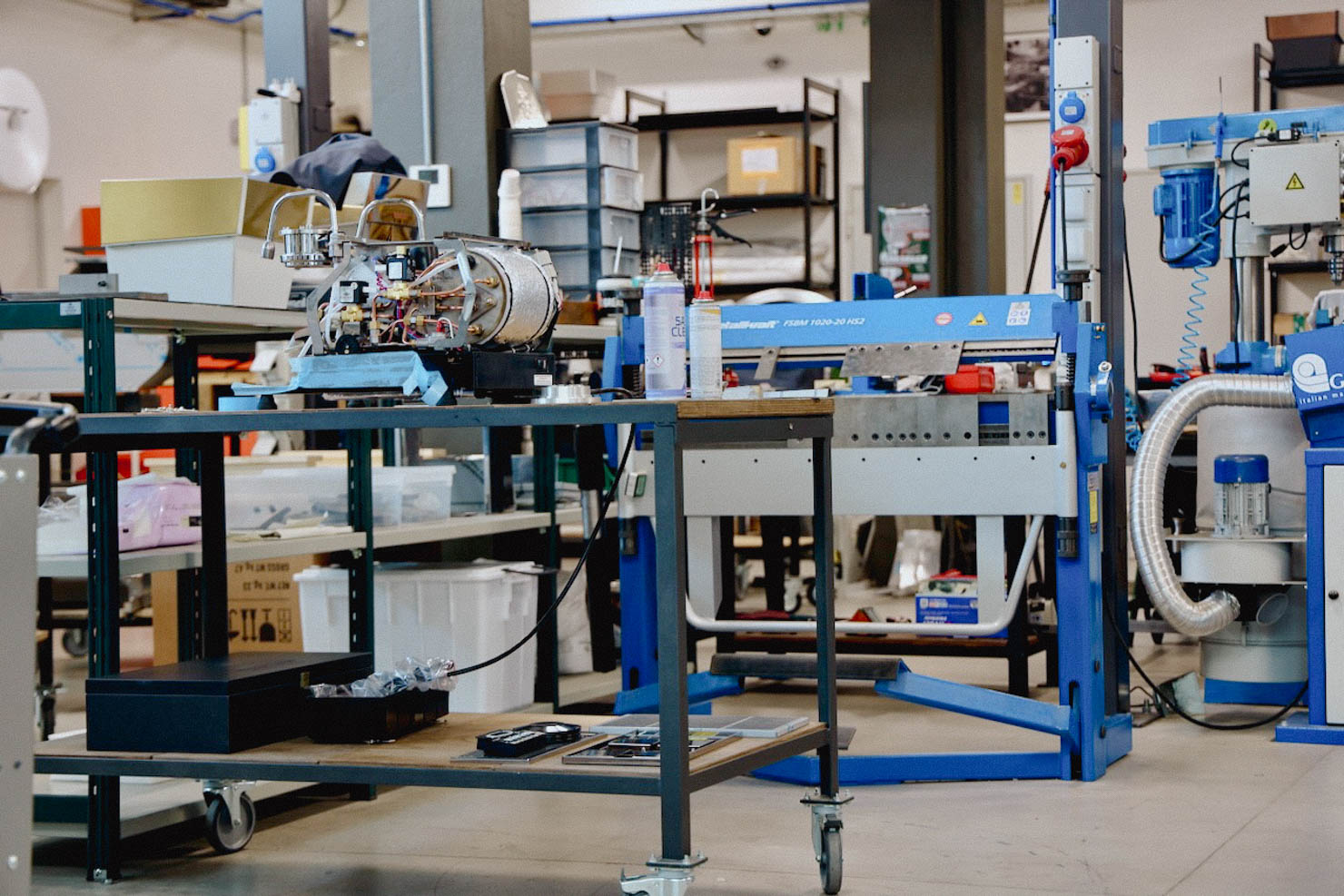

Down two flights of stairs, beneath the cupping labs and living horticultural garden, sits a traditional espresso manufacturing floor like no other. It is almost hidden but increasingly becoming a major attraction for those in the know, connoisseurs of espresso machine heritage and technology, true believers seeking for a fusion of the old ways with modern technology. In 15 years of writing about coffee culture, I’ve never seen anything like it; I’m not sure there really *is* anything else like in the world today. We started champing at the bit to see and experience this place the moment it was announced, and now today Sprudge is thrilled to take you inside a wholly unique artisan espresso manufacturing space, where truly hand-craftsmanship and traditional tools are fused with state-of-the-art modern technology from La Marzocco.

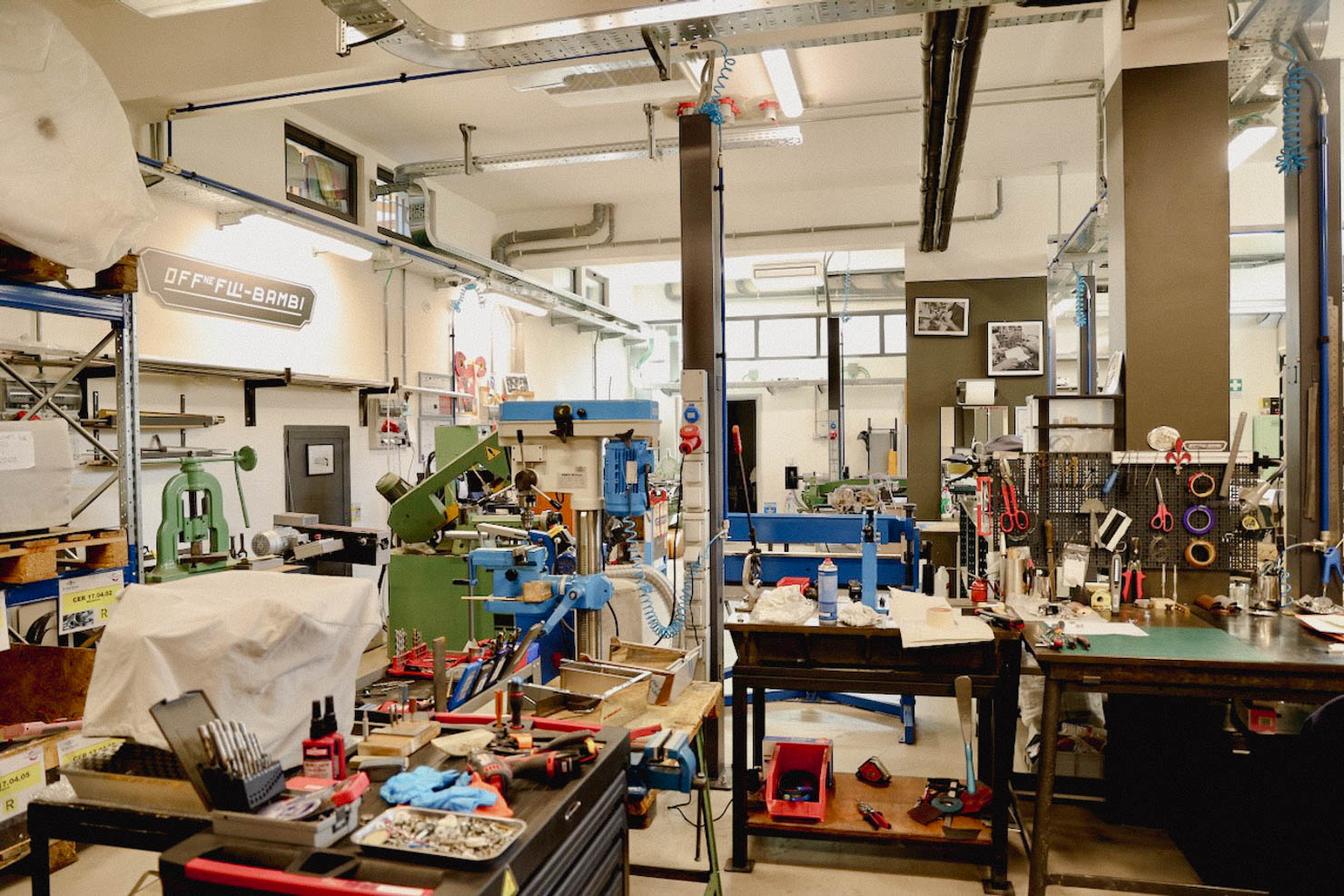

This is Officine Fratelli Bambi.

“We had done customization in the past before, of course,” says Stefano Della Pietra, Head Designer at La Marzocco and Officine Fratelli Bambi, “But we wanted to create a design hub. We wanted to allow for both R&D and customization to stay in Italy, in Florence, our home.”

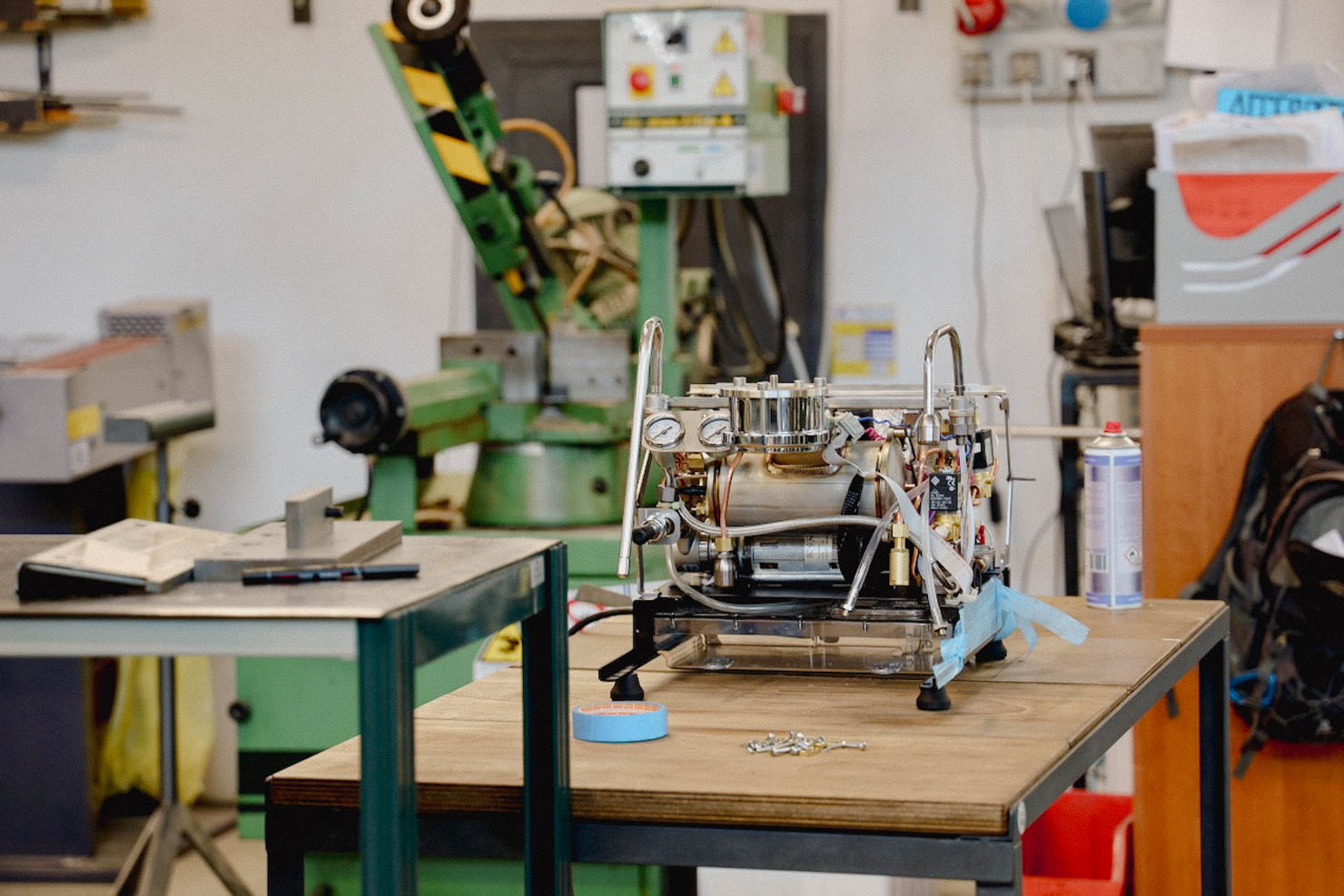

Working in a traditional way allows the team at Officine Fratelli Bambi (which includes Stefano Dello Pietra and artisans Lorenzo Carcasci, Lorenzo Santoni, and Jody Pacini) to keep a living connection to La Marzocco’s traditional design heritage. Cutting, bending, welding, and polishing machines by hand in a team that includes just five highly skilled artisan craftspeople. The end result feels like an atelier for espresso machines, drawing on the Italian tailoring tradition (which is especially strong in Florence, home to Pitti Uomo) so as to quite literally “draw” designs and patterns directly into raw materials, like master tailors working with steel.

Straight lines are cut with huge blades, while more defined lines are cut with scissors and hand saws (there may be a bit of shrapnel, so watch out). “Different metals present different difficulties for realizing design,” Stefano Dello Pietra tells me, as we walk past raw material of stainless steel, aluminum, copper and brass. “Every single material has a different behavior.”

The atelier produces around 25 machines a year, and while some tasks can be delegated within the small team, other more difficult tasks are managed by a single skilled designer. This attention to detail results in a process that works at a more traditional pace, certainly in comparison to, say, the ultra-modern state-of-the-art design floor producing Linea Minis and Micras we saw further up the hill, at La Marzocco’s main manufacturing facility in Scarperia.

Bending machines with modular blades allow the designs to bend and corner metal; these vintage pieces of equipment are operated with manual lever controls, allowing a high degree of accuracy. “Working with polished stainless steel is the most difficult,” Dello Pietra says, “because nothing can be hidden by paint.” The machine itself dates to the late 1960s, and other equipment at Officine Fratelli Bambi dates back even further, to the 1950s post-war manufacturing boom. Another machine, which is called a “radius bender”) presents as a series of machine cranks, and looks a bit like something an Italian grandmother would use to make pasta. This allows the Officine Fratelli Bambi team to create a perfect cylinder from flat metal, which is both simple and astonishing to watch.

There is not a single computer on the floor of this manufacturing plant—it is wholly like stepping back in time, to a 20th century era of artisan espresso design. But there is technological influence all the same, beneath the surface. 3D drawings happen in a separate room downstairs, allowing the designers to harness the precision of modern tech and apply it to their vintage equipment. And a unique partnership with the University of Pavia has allowed La Marzocco to make use of a state-of-the-art 3D metal printer for stainless steel printed components, including custom molded single pieces, which are then hand polished and finished at the factory as needed.

We come upon a finished machine, which is coated in stunning hammered aluminum, creating an almost 3D curved effect. This is the result of intricate work: radial bending and sloping, pinching the material to make it rounder and perfectly finished, slowly brushed and refined. Welding is an important part of the process as well, and perfect welding is the result of careful execution. “There is no mold, no plastic,” Stefano Dello Pietra tells me.”As much as you can be precise in cutting and welding, the more room you have to be beautiful.”

“Realizing things in these traditional ways is not easy,” he continues. This artisan work is what we have in our DNA. It is the artisan realization of a machine. When you say ‘handmade’ to someone, not everyone understands… but when you come in here it’s obvious. You cannot hide anything.”

Well, almost nothing is hidden. In the course of our visit to Officine Fratelli Bambi we’re shown a series of limited edition machines and prototypes which we are not permitted to discuss or photograph at this time. This atelier also functions in part as something of a skunkworks for La Marzocco, allowing them to develop limited edition projects and iterate on design in a manner that draws on the extensive experience of OFB’s small team. The limited edition projects you’ll like on Instagram next year are here today, being carefully iterated on by a small team of design artisans.

Some of what we saw on this visit, you just have to see it yourself to believe. If you count yourself as a fan of espresso machines—as someone who loves the history and culture of espresso technology every bit as much as you love a good shot of the finished product—a visit Accademia Del Cafe Espresso in Florence ought to become your next pilgrimage. There is nothing else like it on the planet. But downstairs, among the true artisans working within Officine Fratelli Bambi? That’s where the real magic happens.

Jordan Michelman (@suitcasewine) is a co-founder at Sprudge Media Network, and the winner of James Beard Foundation and Society of Professional Journalist awards. Read more Jordan Michelman at Sprudge.

Photos by Sprudge co-founder Zachary Carlsen.

La Marzocco is an advertising partner on Sprudge Media Network.